Application of titanium dioxide in chemical fiber

Because the molecules are arranged in order, the surface of the chemical fibers is smooth and has a certain transparency. When illuminated by light, the fibers can produce auroras which is a strong sheen that is unpleasant to the naked eye. In order to make the chemical fiber similar to the natural fiber's opacity, under the premise of not affecting the strength and tensile properties of the fiber, a certain proportion of the matting agent is usually added to the chemical fiber through spinning to get the semi-dull or full dull chemical fibers.

Chemical fiber spinning is a complex process. Improper selection and use of titanium dioxide will inevitably affect the production and final performance of fibers. Therefore, it is necessary to have a comprehensive understanding of the properties, quality requirements, and applications of titanium dioxide, so as to ensure the fiber quality and achieve the best matting effect.

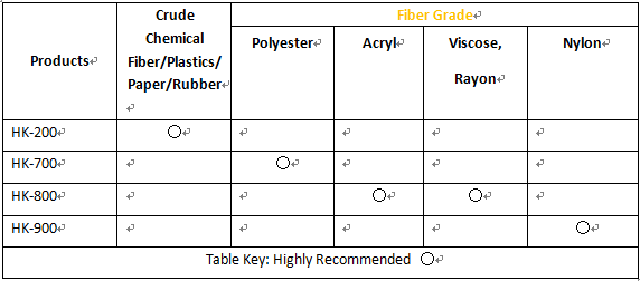

Among white pigments, titanium dioxide has the best optical properties, i.e. the best matting effect. It is mainly used as a matting agent in chemical fibers. According to the crystal shape, titanium dioxide can be divided into three types: rutile, anatase, and plate. The plate type belongs to the rhombic crystal category, which is unstable and thus has no practical value. The rutile and anatase types belong to the tetragonal category, the former has a larger relative density and hardness due to the dense atomic arrangement. Rutile titanium dioxide has a larger refractive index than anatase titanium dioxide, but it is likely to wear spinneret holes and cutters as a result of high particle hardness. Therefore, anatase titanium dioxide is usually used as a matting agent in chemical fibers.

The addition of the titanium dioxide matting agent not only plays an important role in the matting of chemical fibers but also affects the properties of fiber polymers, machine wear degree, service cycle of filter components, end breakage rate in spinning, and the physical and mechanical properties of fibers. Therefore, the amount of matting agent should not be too high but should depend on the degree of matting required. Generally speaking, when the amount of titanium dioxide matting agent added in is 0.27%-0.3% it is half dull, while adding 2.3%-2.4% is full dull.